The Eastern Long Island Mini Maker Faire took place on Saturday, June 10, 2017 at the Port Jefferson Maritime Explorium. For the third year in a row, SBU iCREATE (previously known as the SBU Innovation Lab) attended the fair featured as one of the makers, and tabled with several different family-friendly, interactive activities including 3D Doodler pens, a PacMan robot maze, DIY arm braces, and 3D puzzles made of cardboard and balsa wood.

As described by their website, the Maker Faire is “a gathering of fascinating, curious people who enjoy learning and who love sharing what they can do.” The makers could be anyone, ranging from engineers to artists, and is a family-friendly showcase of the interesting things people do in the spirit of innovation, creativity, resourcefulness, and invention.

The impact of attending and tabling at this event reached both iCREATE staff members who attended, and attendees of all ages who stopped by our stations.

Several of the stationed activities were an instant hit, with lines and crowds throughout the entire duration of the event. They were evenly split, designed with two goals in mind: to engage people in technology, and to encourage thinking “out-of-the-box” with those who did engage.

The PacMan Robot Race, Google cardboards (VR), and 3D Doodler pens all use technology to capture the visitor’s attention with the way they work. Not all of these new technologies are readily available to the average person or visitor. By exposing them to this new perspective, they are thinking in new ways. It inspires them to experiment and be creative by testing it out.

The others, being the arm braces, 3-D puzzles, and Vision Trainer showcase, are bits to takeaway as “food for thought” after the demonstration/interaction or explanation. It encourages the visitor to think creatively and not in a way he/she typically would in a normal environment. It allows them to create something new and original through innovation.

One of the more popular stations, the 3D Doodler pen station could be summarized as frustration – but in the best way. Learning how to use the pen comes with a bit of a steeper learning curve. It’s not the easiest skill to pick up, but using it is intuitive. With some practice on control of the pen and the filament, more complex designs and patterns can be created. For example, some creations iCREATE student staff have made include a tricycle, a colored cup, a tree, and a figure of a small person surfing on a little board.

Of those who visited the station, it was a familiar-yet-unfamiliar item that most have at least heard of, or seen somewhere on the internet. The 3D Doodler pens are an increasingly common “toy” being introduced to the public. Famous for their “draw in mid-air” pitch, the pens captivate audiences of all ages. While the buzzword “3D printing” is extremely capable of drawing people, it also deters those who feel they are not tech-savvy or advanced enough to play or experiment with it. Exposing people of all ages to how simple and easy it is to use breaks a lot of barriers.

Some people picked it up immediately, making intricate designs and patterns freehand. On the other hand, some struggled with keeping the filament from sticking to itself. They were all so intrigued by the possibilities of what they could create with the pen, that our staff were kept busy the entire event.

“There was one girl who was playing with the pen, but her father told her to let the other kids play, and she started crying because she didn’t make anything,” Jennifer Ng said, a staff member who worked at the Doodler station, “ Because she hadn’t used the pens for long at all, I offered to help her make a house that she was able to take home. Instead of doing it for her though, I held the top end of the pen to guide her while she controlled the button, and after a little while, she was able to create a house with my help. This was one of my more memorable encounters because I was able to help a young girl create something that she could be proud of without having to do it for her.”

One station, the PacMan robot maze was a crowd favorite among both children and their parents. Children and parents alike waited in line, waiting for a chance to beat the high score and to get their name on the board. Visitors raced each other by recording the amount of time it takes for each person to go through it. The difficulty comes in where it is slightly hard to control in terms of direction and speed. The Sphero is a fun and interactive, and introduces any beginner or person of any level to robotics in a simple, hands-on way. We had a whiteboard present to get peoples’ names, ages, and times, and it adds a competitive edge to it, because everyone wants to get the fastest time.

Director of iCREATE, David Ecker said, “I think the concept of the PAC Man race was the best way to teach by doing a learning game. This game was teaching them how to interact with a technology they were familiar with, the iPad, and control a robot that was strange to them. This allowed some of them to overcome any fear they had using the unknown robot, then develop a level of confidence to actually race around the maze. These are exactly the basics of learning through using a game platform.”

Rohan Kingan, a staff member who worked at that station said, “It seemed like most of the kids interested in playing the Sphero game were ages 5-13, but the parents were pretty interested in it too. We had one 31 year old who was pretty set on beating the high score, so that was pretty funny. The high score whiteboard really caught a lot of interest. People wanted to have their name up there, motivating them to come over and try, or try multiple times.”

By the end of their turn and the wait, parents had many questions. Staff members received constant questions on how the robots worked, how they moved the way they did, and even how much the Spheros (robots used) were and where they could find one for their kid(s).

“I know the interaction that Rohan had was positive in teaching all ages on how the robotic movement worked inside,” David said, “It gave them a better idea (especially with the clear one) on how the internal mechanisms allows for the ball to move in different directions.

The excitement doesn’t stop at just the 3D Doodler pens and Sphero robots; the other stations such as the 3D puzzles and DIY arm braces piqued a lot of passerbys’ interests.

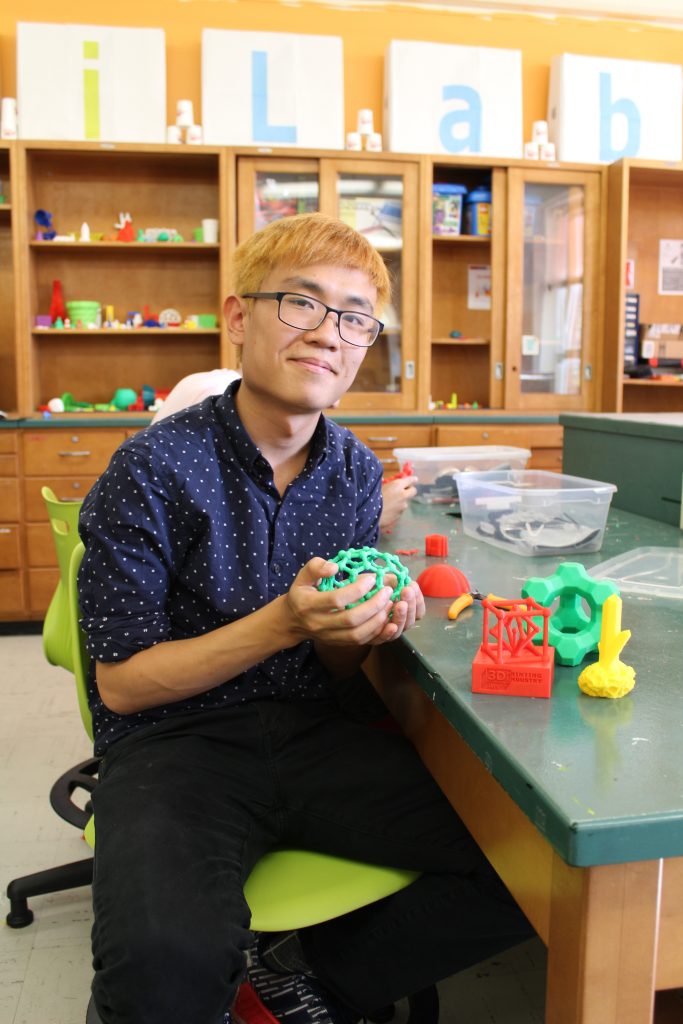

The 3D puzzles were prepared by one of our staff members, Ahsanul Torza, with iCREATE’s new laser cutter. This tool has not yet been opened to members of the facility, because research on safety regarding what it can handle and create is underway, but simple projects such as cutting balsa wood has been popular. It was a showcase what iCREATE’s facilities are capable of, and also to engage people in finishing the puzzle.

The puzzle was created by laser cutting the template out of the wood, and punching out the pieces. Each piece was a different component of the object. The pieces were then assembled to make a 3D object, as opposed to the average 2D jigsaw puzzle. Alike the 3D Doodler pens, some take to it immediately, while it takes some longer to adjust due to the added dimension and level of difficulty from the average puzzle.

The DIY arm brace station came with its own background story. There was a hypothetical situation: “You are with a friend on a trip, or at a playground, when suddenly your friend falls and breaks their arm. The fastest the closest ambulance or medical help can arrive is several hours away, and the contact over the phone informs you to stabilize the arm so it does not break or shift any further. Of the limited resources available, you need to keep the arm still and from breaking further so that they do not hurt themselves more. What do you do?”

Children had a number of supplies to work with, including gauze, cardboard pieces, string, and band-aids that could be used creatively to help your friend. Thosen who stopped by would have to “think on the spot” with those supplies and create an arm brace of their own. It was unique because it is similar and accurate to how a real-life situation could be when one need to innovate and improvise on the spot.

Jennifer said, “It was great to see a lot of kids running around with the arm braces we brought as well, because the activity is something that is applicable to real life, and introduces skills that could be useful should they ever get into a situation where someone gets injured. Though the arm braces that we made may not necessarily work if someone were to actually break their arm, the activity shows kids that, even with limited supplies, they have the ability to create/build things they need.”

“By the end of the event, some kids were asking each other and some of us if we would sign their casts,” said Sera Nakisli, another student staff member.

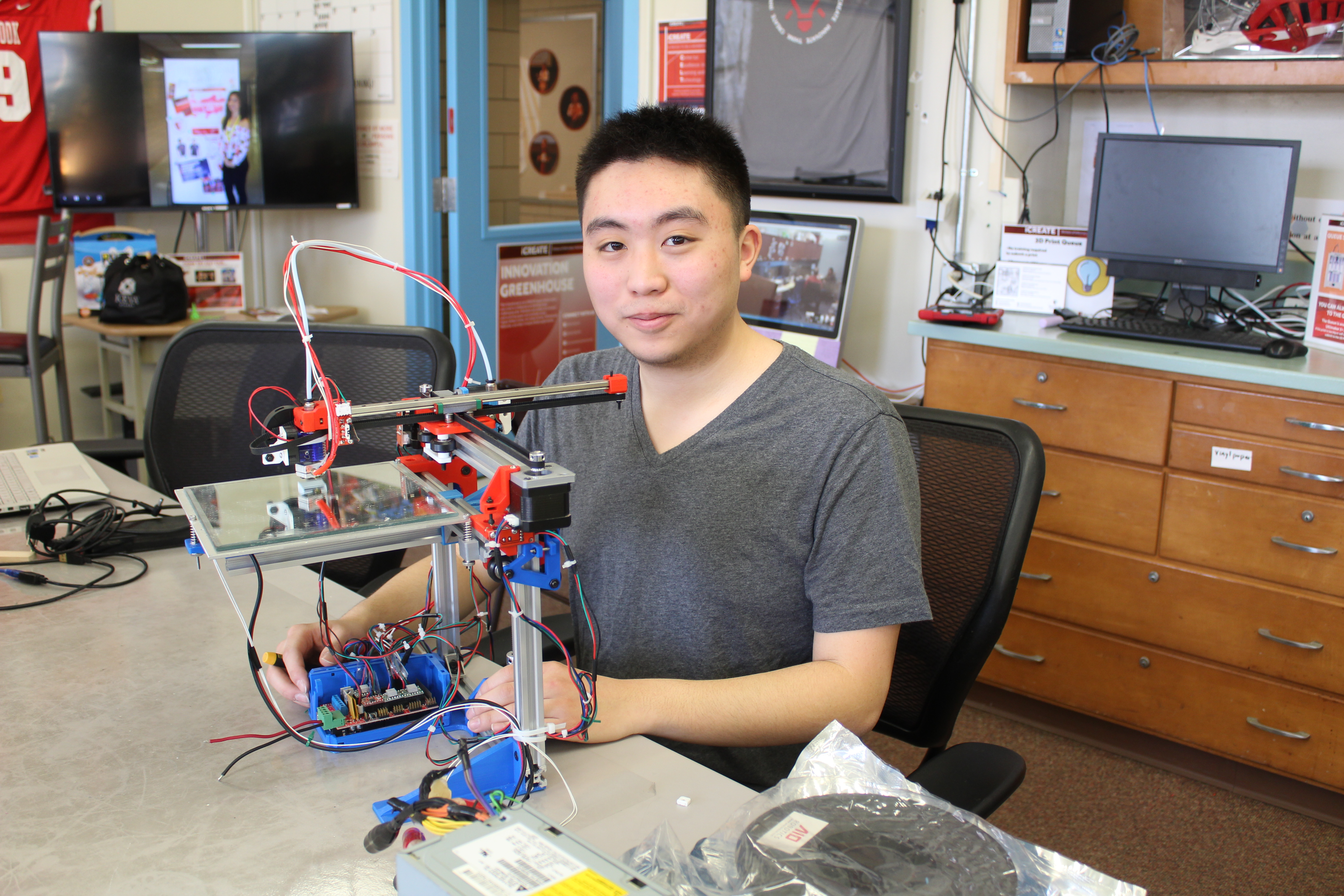

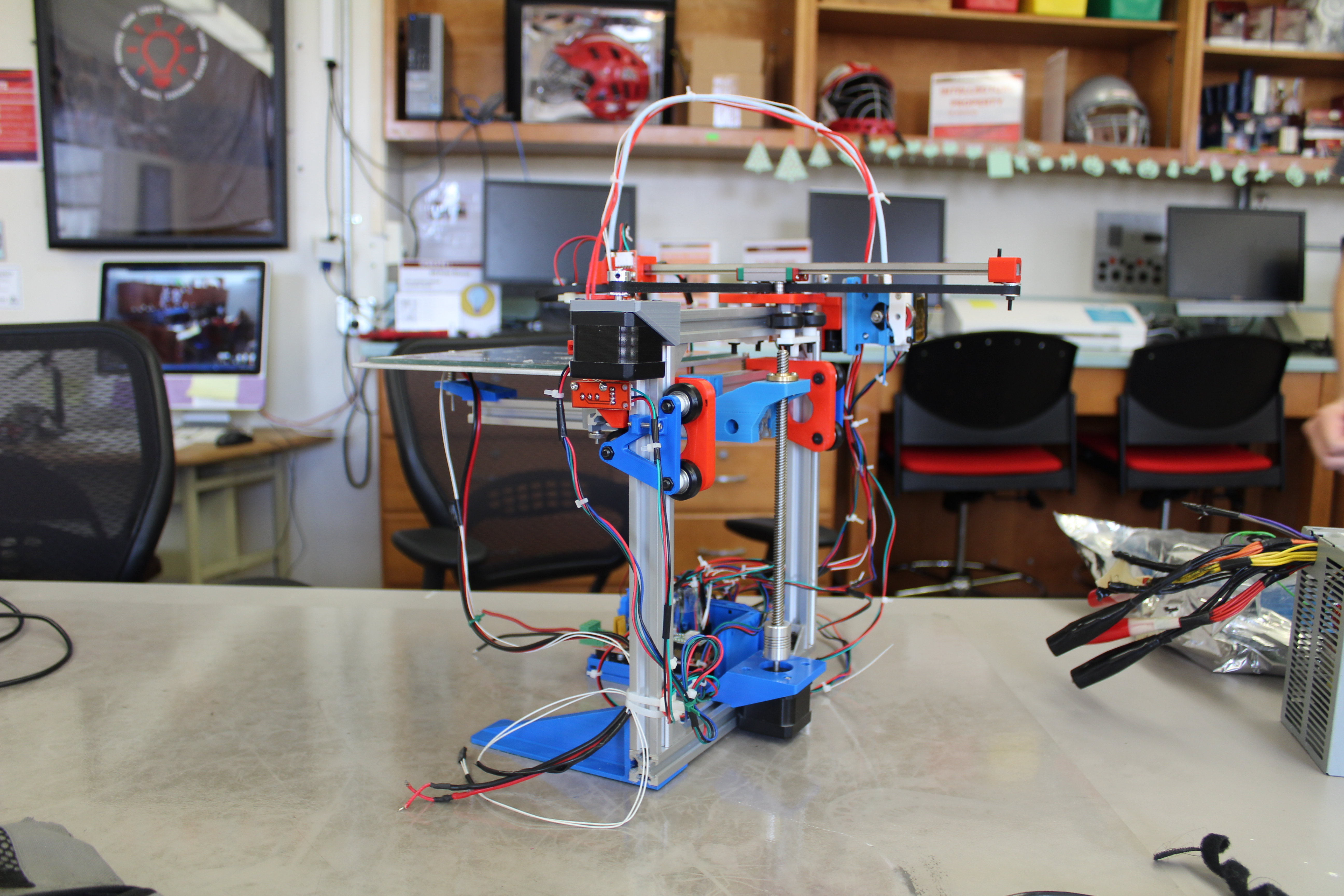

One station was the Vision Trainer project. It was a showcase: though originally planned to be a demonstration, it was not possible to fix it or get it to work. This was due to the incompatibility of motor parts from the limited budget and availability of necessary parts to make it run correctly. Unfortunately, its current configuration causes the motor to burn out quickly and does not allow it run the way it should.

As such, this was used as an example of how innovative ideas are born, created, worked on, and also how it doesn’t always work out.

By the end of the event, iCREATE staff members found it memorable, and felt like it was a success to the community and for iCREATE. Ahsanul said, “We had a lot more traffic than last year, and we did a lot better. I didn’t stay for whole thing, but the kids were reacting a lot more enthusiastically.”

Narmin shared, “It was really cool that our activities has a wide audience of people ranging from adults to young kids. For the DIY arm braces, I gave one girl two braces so she had two arms with it!”

Overall, iCREATE’s attendance at the MakerFaire was able to influence children and adults with fun, interactive, hands-on activities, and creative thinking. David said, “As I see it, the hands on activities that were developed and taught allowed the community find a place to enhance their knowledge and skill set around new technology, which is why we exist. It is to allow new ideas to be developed and implemented through thinking, creating, and innovating. Our table made that accomplishment through examples like the successes with the maze and the failures with vision trainer.”

Above: Shot in Starbucks on campus, with the copper string lights and leaf shaped filter.

Above: Shot in Starbucks on campus, with the copper string lights and leaf shaped filter. Above: A portrait shot with the leaf bokeh filter.

Above: A portrait shot with the leaf bokeh filter. Above: Shot with a snowflake shaped bokeh filter.

Above: Shot with a snowflake shaped bokeh filter.

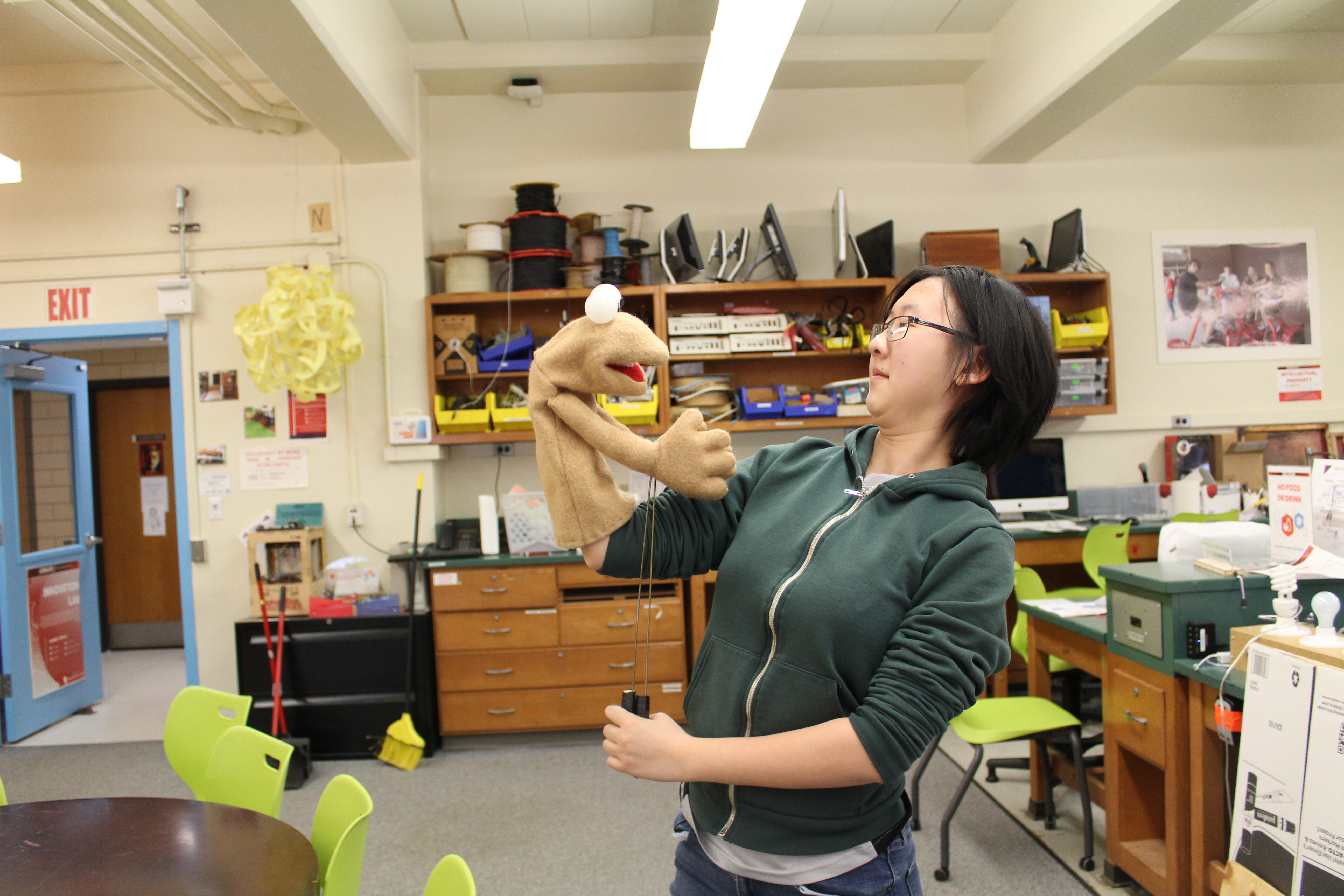

A staff member using the Innovation Lab’s sewing machine.

A staff member using the Innovation Lab’s sewing machine.