AV services, a part of Department of Information Technology (DoIT), teamed up with the Innovation Lab earlier this month to work on a special project – creating new stencils for its equipment. Rich Fantasia, a part of the AV staff at Javits center works to provide instructional support to faculty and staff with the various classroom equipment and technology. He also maintains both the old and new equipment as the department gets new items to freshen up the inventory periodically. There is a standardizing procedure that all equipment needs to go through. Each item is entered into the system, given its own control number, and labeled under AV Services.

After using the same, old, worn cardboard stencils over and over again, Rich Fantasia decided that it was time for an upgrade. The cardboard stencils were worn from being cleaned over multiple uses, and did not work as well. It also took a very long time to individually label each number onto the equipment, because multiple numbers needed to be put onto each piece of equipment. The ideal product of this sounded simple: something durable and flexible, easy to clean, and shuffle around numbers. First, he looked into TLT Media Lab, another subdivision under DoIT, only to realize that they specialized in different areas than from what he needed. Then, the Innovation Lab came to mind, from its e-mails and growing presence on the campus. He came in with his concern, consulted with our staff, and was able to work with Taylor Campbell to find a solution.

Taylor Campbell is one of the Innovation Lab staff members. She is a junior and mechanical engineering major who started working at the lab over this past winter 2016. Taylor is a part of the 3D print team – responsible for handling the print queue, printer-related problems, and help on special projects. Working with the stencils for AV Services was her first project at the lab.

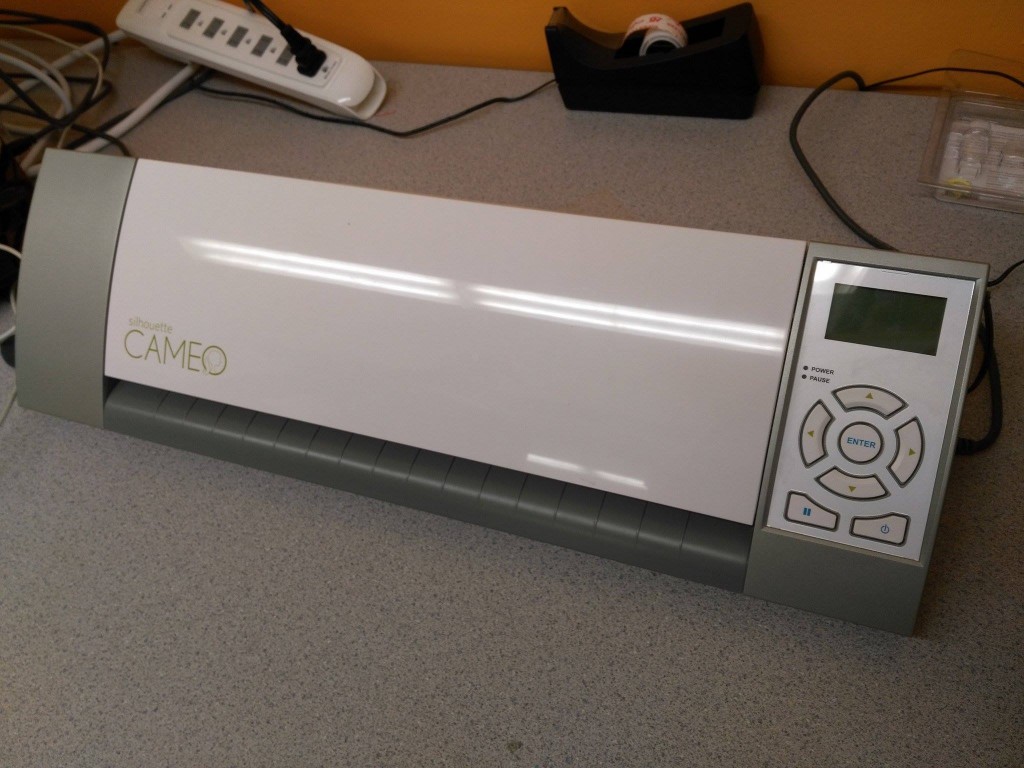

The Innovation Lab’s vinyl cutter, and its respective sign on the wall of the lab.

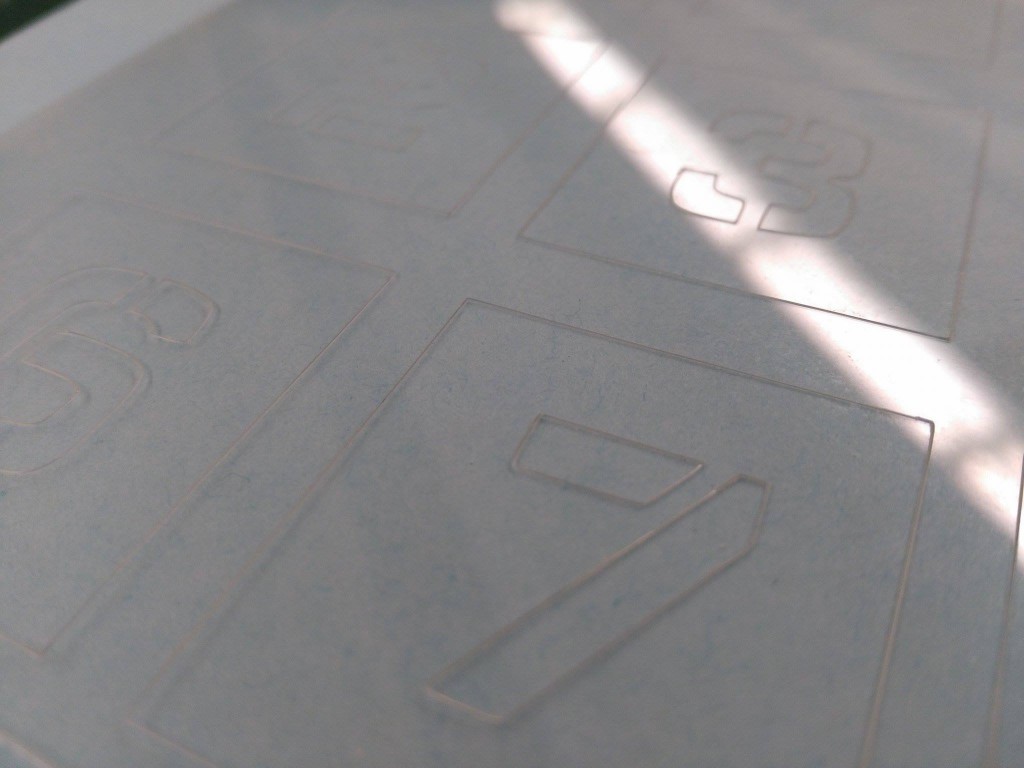

To make the stencils, Taylor learned to – and successfully – use the Innovation Lab’s vinyl cutter. Rich Fantasia was able to provide a PDF file of what he wanted the stencils to look like, with the words, numbers, and sizes needed for each. Taylor manipulated the file in the program and printed out samples on cardstock. This also allowed her to get familiar with the program for the vinyl cutter, as well as to test out how it printed. It takes some level of familiarity to be able to adjust the vinyl cutter to cut into the material correctly due to its specificity on the thickness of the material it is cutting into. After the successful run-through with these cardboard duplicates, she switched to a durable, flexible medium-weight plastic. They would last longer over time than cardboard, and would make it easy to clean and wipe off after use. It was also flexible enough to wrap around rounded surfaces – another limitation the cardboard stencils struggled with.

Taylor demonstrating how the vinyl cutter was used.

Some examples showing several different designs of the stencils that were made.

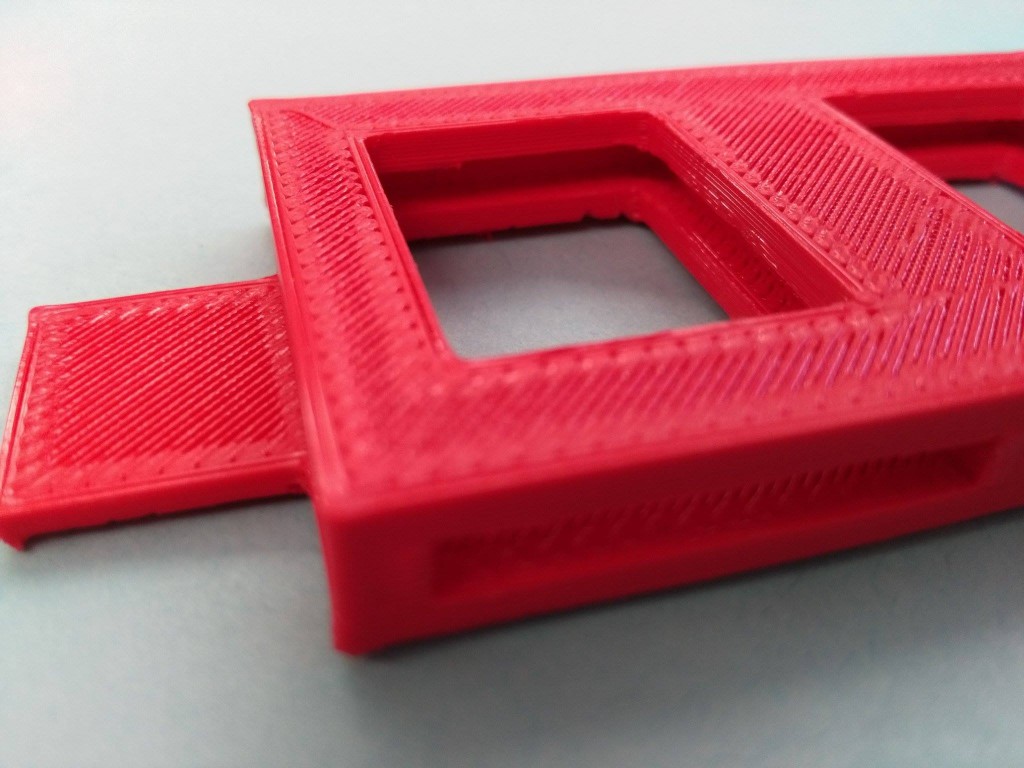

Aside from the plastic stencils themselves, Taylor also specially designed and 3D printed a holder to fit the number stencils. She designed it so that could hold two number stencils at once while still allowing the user to shuffle them out easily as needed. This would resolve the issue with the tedious time commitment previously required to label equipment with numbers. When Rich Fantasia saw the final results of the stencils, he could not be more satisfied. “It’s amazing; it’s exactly what I had in my mind. It’s beyond what I asked for, because she invented something to solve what I asked for.”

Taylor’s custom printed number stencil holder. In the first picture, we see the slot for how the stencil is inserted and removed. In the second picture, we see an example of how it would look with a number stencil in it.

After seeing the tour, and the work that has been done so far, Rich Fantasia says that he believes the Innovation Lab is a great resource on campus, and that he would definitely see the lab again for future projects and/or problems that come up.

This collaboration between AV Services and the Innovation Lab is a great example of how 3D printing and creative problem-solving can lead to practical, efficient solutions. By upgrading the old cardboard stencils with durable, flexible plastic versions and creating a custom holder, Taylor Campbell successfully addressed the challenges faced by AV Services. Rich Fantasia’s satisfaction with the outcome highlights the value of innovation in streamlining processes and improving workflows, and it’s clear that the Innovation Lab’s interdisciplinary approach can provide ongoing support for future projects LiteBlue Lite