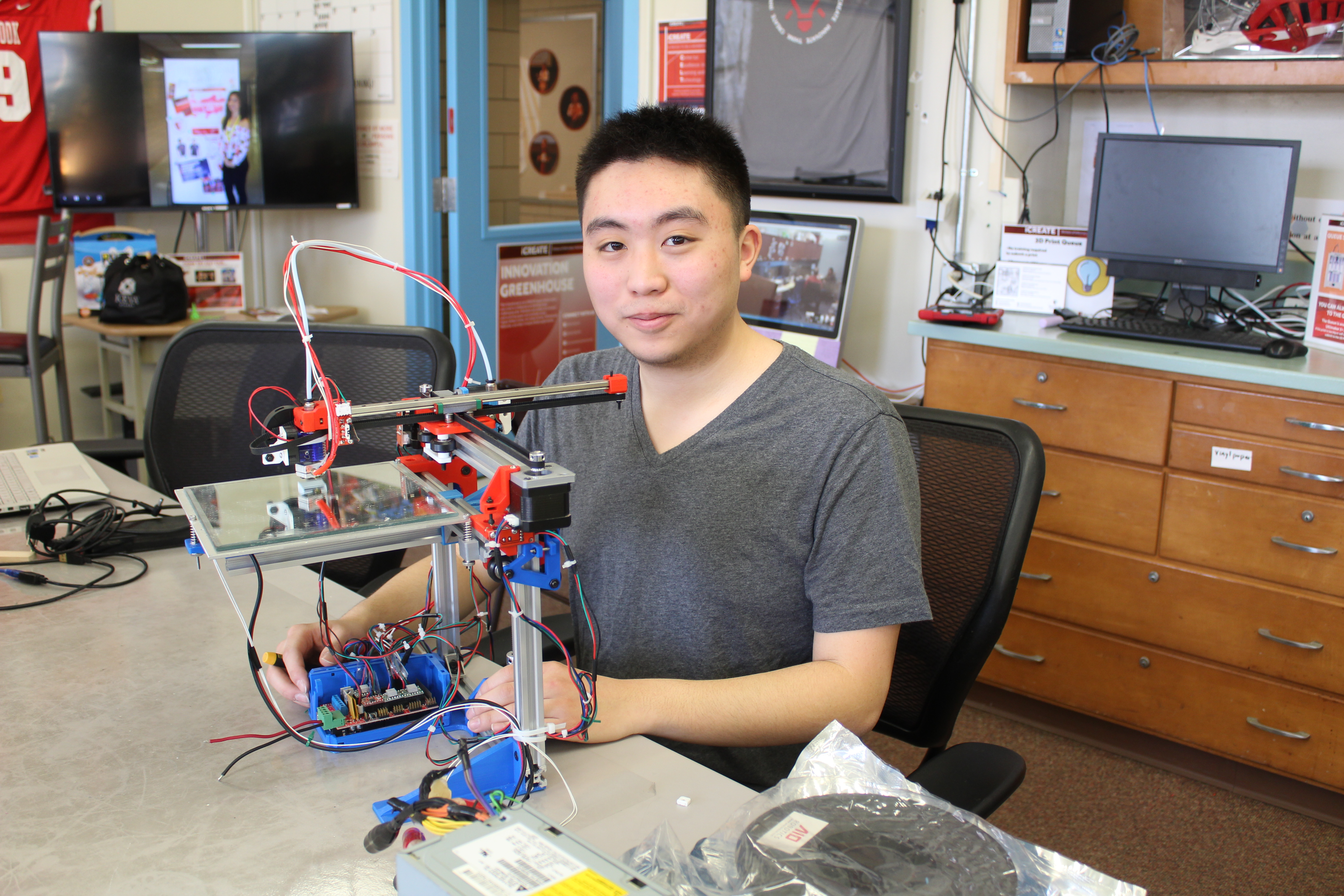

Brian Yang is a senior with a double major in Biology and Economics and a minor in Chemistry. If that’s not enough, Brian also has recently taken up additional innovation projects — the biggest of which is building his own 3D printer. Brian received a commercial 3D printer as a gift.

Something in Brian was sparked, and a new passion was ignited. Brian began to learn more about 3D printers and the technology behind them, and was eventually inspired to create his own by the RepRap Project. The RepRap project — short for Replicating Rapid-prototyper — is an initiative to create low-cost 3D printers that can 3D print most of their own parts (You read that right. 3D printers are being made to 3D print more 3D printers.). It is now a global project with free designs and licenses for anyone to use.

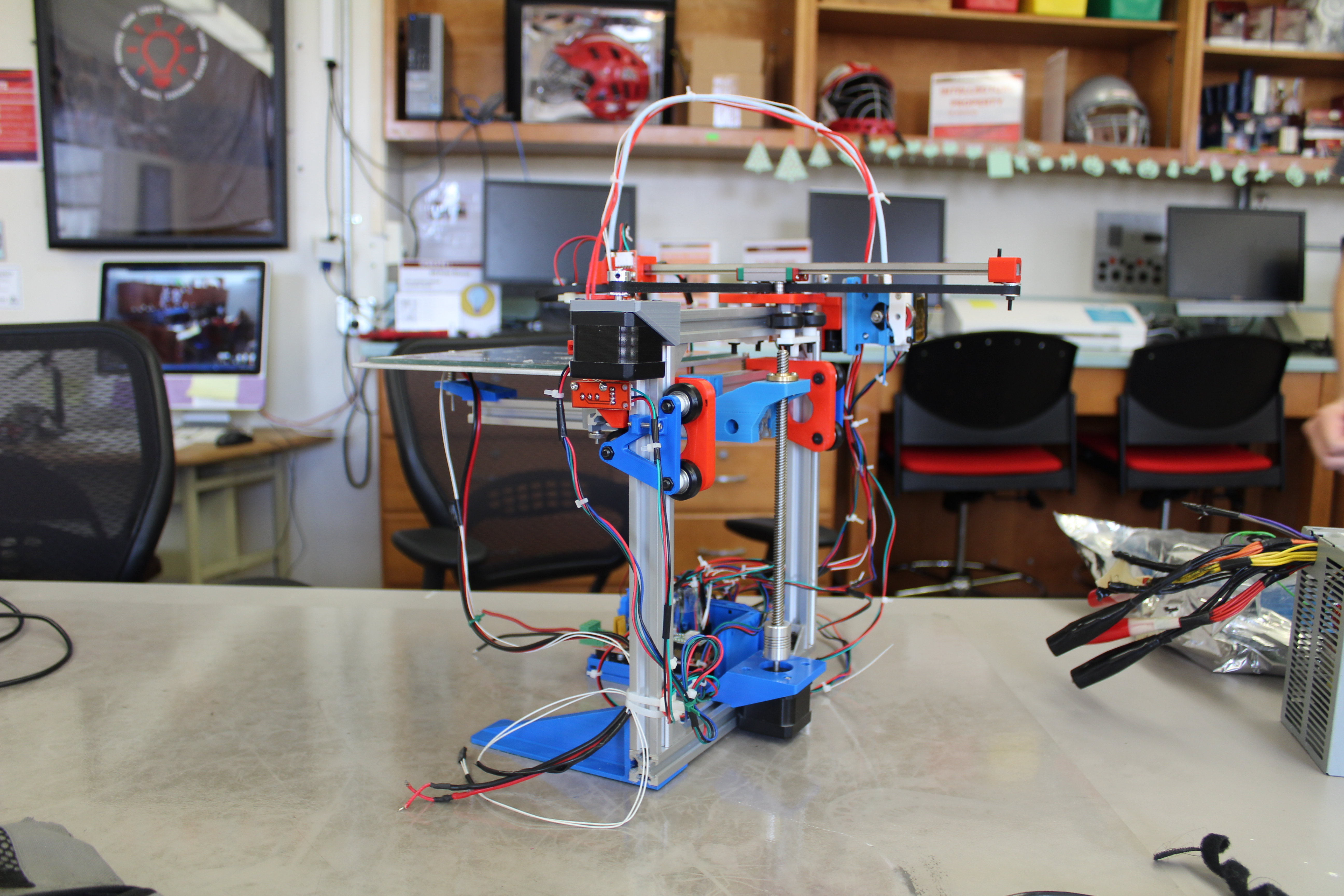

When Brian realized that this was something he wanted to do, he knew that the Innovation Lab was the place to go. He designed all of the 3D printed parts of the robot himself using Autodesk Inventor, and went to the Innovation Lab to physically print as well as utilize other tools such as soldering irons, screwdrivers, pliers, and general help from the Innovation Consultants on how to execute the project and make sure it was unique.

Brian wanted to make his printer different than others already out there. He thought he could maybe do better. His printer is a parallel robot instead of the typical serial robots on the market. By using a different layout, he was able to both reduce the amount of frame and open up the print surface. The pros of these modifications are decreased costs and increased visualization. The disadvantage to this layout, Brian found, is that because the gantry is cantilevered, it is less stiff and can bend under the weight of the printer head. Brian hopes that experimenting with other designs will help others to think more innovatively when it comes to designing new types of 3D printers, and he hopes that his design will help to inspire others.

Brian is currently applying to medical schools and in the future wants to work as a doctor rather than an engineer. However, he recognizes that the fields are merging. “Biomedical engineering and bioengineering are creeping into medicine.” 3D printing organs is no longer a thing of the future. The world of technology is growing and expanding and Brian feels that, “Because of my work with 3D printing and iCREATE, I feel more prepared to deal with medicine in the 21st century.”

Very nicy thought all Charter Panorama equepment is very furies so that’s great to us.

This article is very wonderful McDVOICE com

This article is very wonderful McDVOICE com

Your thoughts and feedback light the way for others; thank you for contributing to our shared journey. CoveredCalifornia

Brian’s journey from receiving a 3D printer to building his own is truly ADP Workforce Now® inspiring! His dedication and innovation showcase the power of curiosity and hands-on learning.

Enjoyed reading the article above, really explains everything in detail, and the article is very interesting and effective. Thank you and good luck with the upcoming articles starbucks secret menu frappuccino

This information is really helpful for who really needs this. I hope you will many more write post like this. That’s great. I was Socrates GM impressed by your writing. I am happy to see such a topic. Please come to my blog and read it.

Thanks for sharing such great information, I highly appreciate your hard-working skills as the post you published have some great information which is quite beneficial for me, I hope you will post more like that in the future.

I have read your article, it is very informative and helpful for me. I admire the valuable information you offer in your articles. Thanks for posting it.

What a fabulous post this has been. Never seen this kind of useful post. I am grateful to you and expect more number of posts like these. Thank you very much. AARPMahjongg

This article is really amazing i hope we will see again this type of article in future..

EHallPass Website

Thank you for your insightful contributions Renta Ciudadana Prosperidad Social

I like the way you made this article. Short but juicy. Thanks for sharing! imedicarecard.com

I was actually reading your article and found some really interesting information. The thing is quite clear that I just want to thank for it.

myaarpmedicaress

Thanks to this article I can learn more. Expand my knowledge and abilities. Actually the article is very real.

Thanks for the info I will try to figure it out for more.

Thanks to this article I can learn more. Expand my knowledge and abilities. Actually the article is very real.SecureSpend card

Thajns for this wonderful information

er

A really good post, very thankful and hopeful that you will write many more posts like this one. I have the same problem with facing same issue but no response from anyone and couldn’t find this topic troubleshooting in search engine. This works really well for us, thank you! nevadanvdmv

I like the way you made this article. Short but juicy. Thanks for sharing!

JPMorgan Chase Bank Card

What a thought I liked your idea I hope you create great project every time and please share with us. SkydivingIndians com

I have read your article, it is very informative and helpful for me. I admire the valuable information you offer in your articles. Thanks for posting it..

Your article content is being very much interested, I am very impressed with your post. I hope to receive more great posts. Click Here

We have compiled this guide to help you with AZMVDNow login, covering all the aspects of logging in and managing your Arizona Motor Vehicle Division Arizona DMV (MVD) online services. AZ MVD Logo If you need help with the AZMVDNow process or want to get on-call assistance by dialing the AZMVDNow phone number, then this page is for you; it has clear step-by-step instructions and essential contact information.

Nice Information Good Work Keep it Up! We are provide the best

123 กีฬา