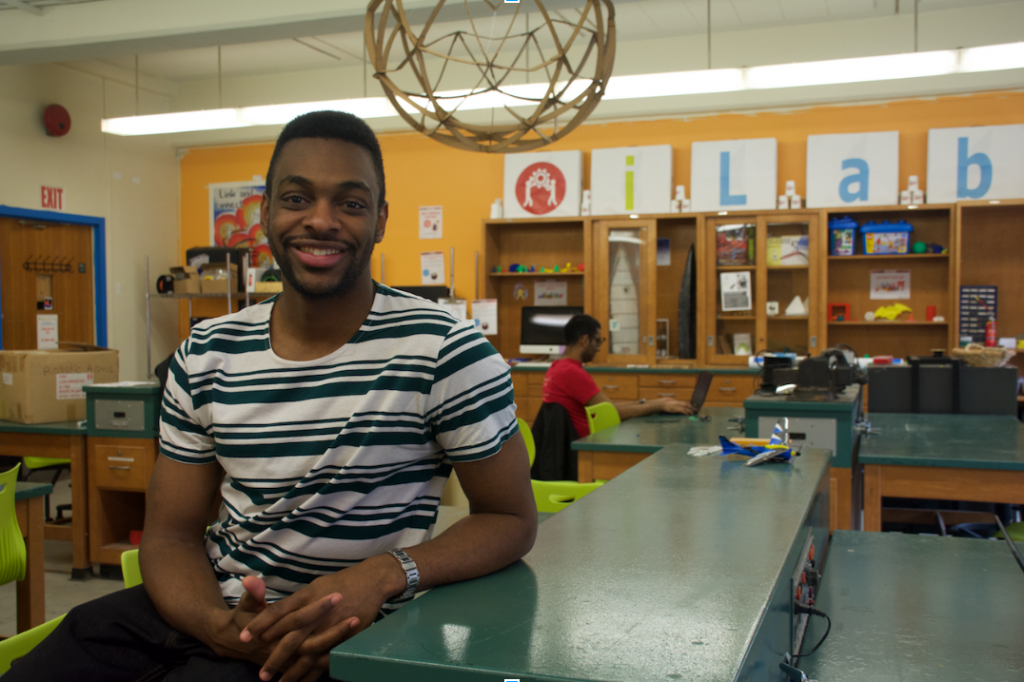

Julian Kingston, a senior Electrical Engineering major and the founding member and President of the Global Innovation Team (now known as CentriSeed Innovations), has a special place in his heart for the iCREATE Innovation Lab. He found iCREATE while he was going through a rough time in his college career when he struggled with his major.

Julian describes the entirety of his college experience as a roller coaster, sophomore year being the steepest hill. “I was dead. My life was school, eat, and sleep.” Going into engineering, he felt as though it was all theory and that it didn’t feel applicable to things in real life, or anything he wanted to do when he originally entered college. Julian spent his sophomore year Spring Break pondering and contemplating plans for the rest of his life before he realized, “I wanted to go abroad and change people’s lives.” His personal and professional journey surrounded his feelings of finding his purpose.

Actively working on building and forming something, Julian pursued forming a new club, at the time Global Innovation Team, with two other colleagues. The Engineers Without Borders chapter on campus was closing and shutting down and all of its eboard members were leaving. Julian wanted to do something more to continue the valuable work they did. Global Innovation Team was born.

“I came and met David [Ecker] at the Innovation Lab and we were discussing entrepreneurship and what ideas I could implement, when suddenly Dave told me to stop talking during the meeting. Dave took the time to show me what others wouldn’t. He saw that potential in me, and that I was someone ready to go do something, but I needed some concrete ideas. I’m never not prepared now.”

Trying to bring a club to life is no easy task. It takes effort split amongst the founding members who push for it, taking up days and nights, and as Julian describes, “like an internship taking up to 10-20 hours a week.”

“I was thinking, ‘I have no idea why I’m in college right now.’ I would’ve dropped out of school. I had no motivation, incredibly hard classes. I didn’t enjoy it the way I thought I would. Becoming an e-board member, being president, having people depend on me, having this responsibility, finding iCREATE’s Innovation Lab – all this gave me meaning to my college experience, and it gave me a purpose to me being here. I thought I was wasting my time in my major.”

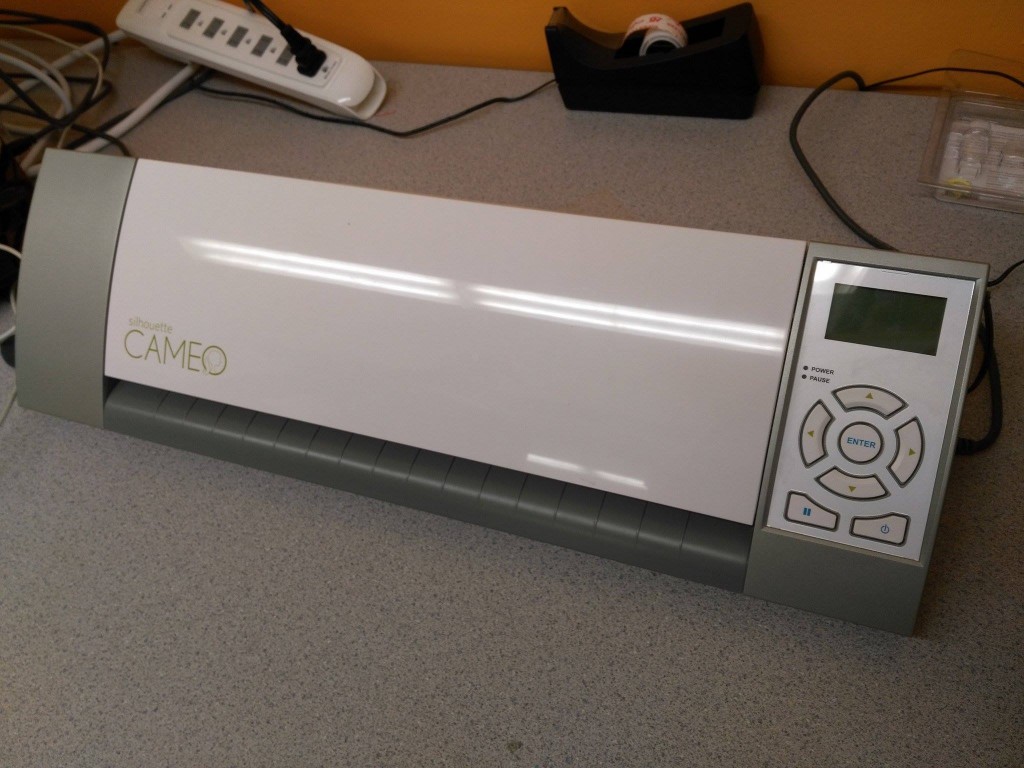

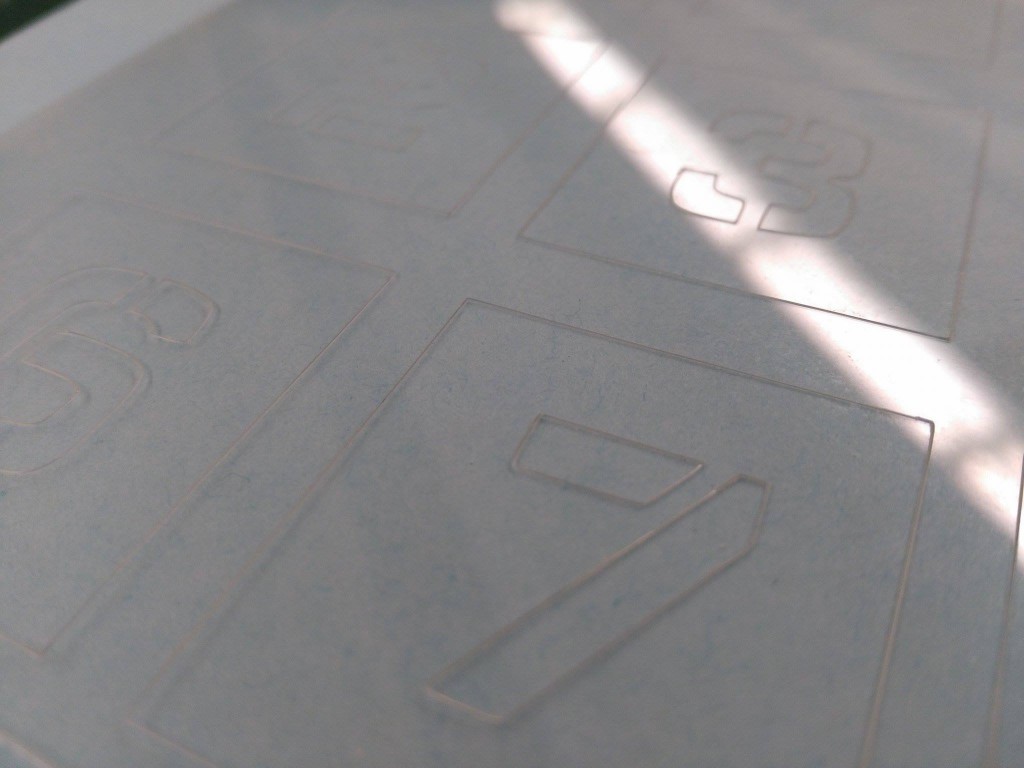

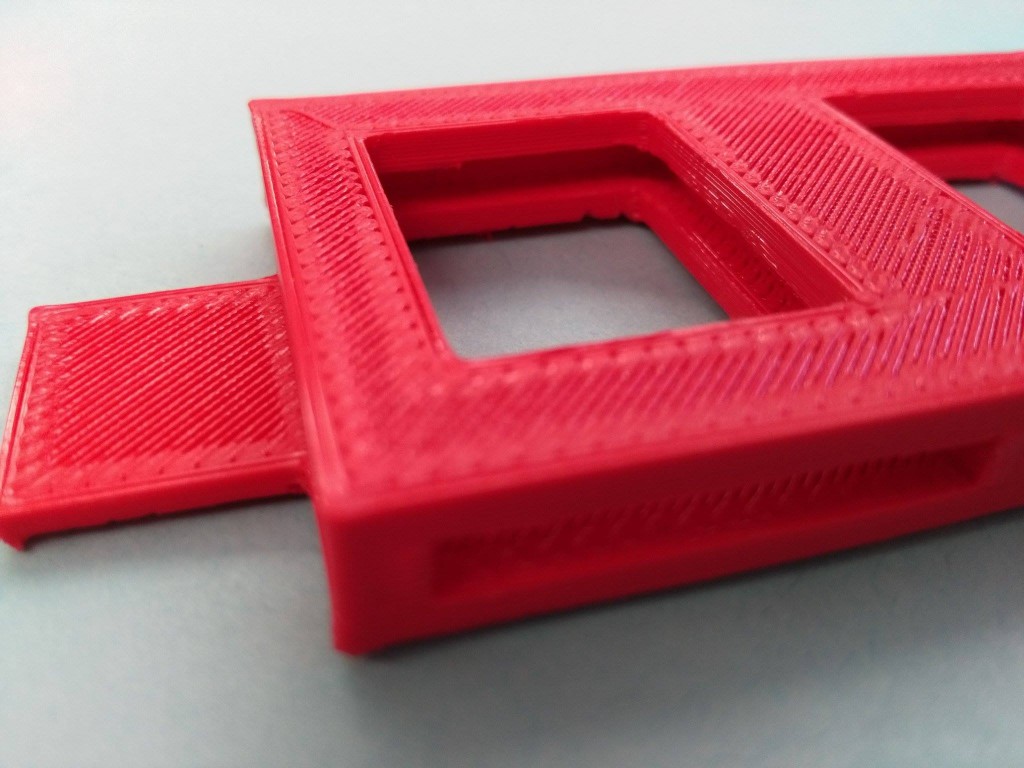

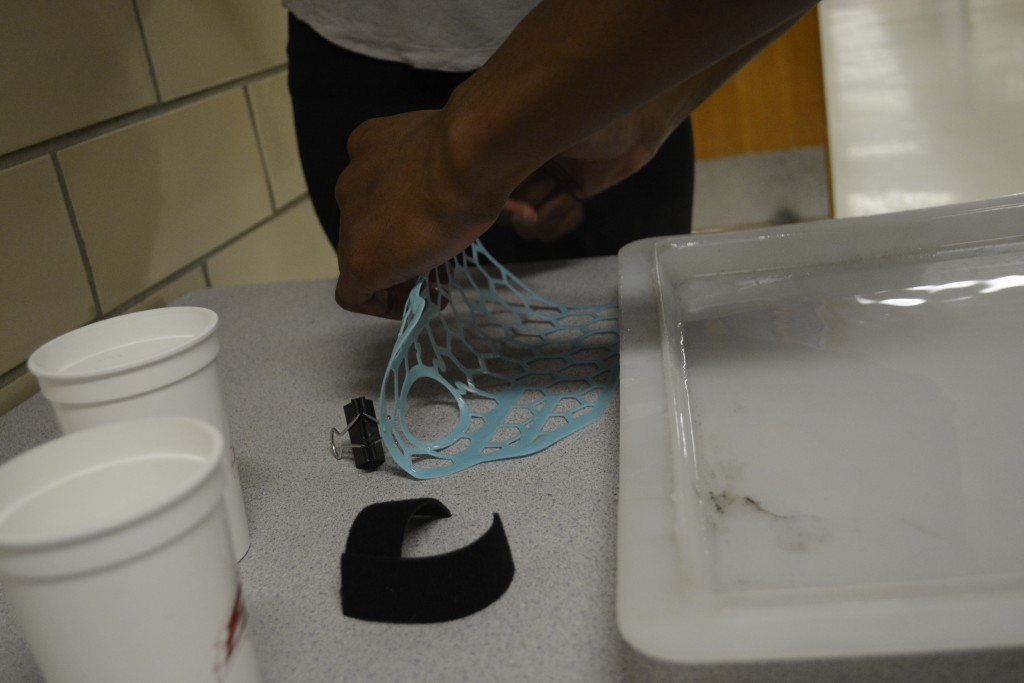

iCREATE’s Innovation Lab was where the members of CentriSeed Innovation made their first moves and projects. They have since worked on Roth Pond’s restoration, the Nobel Halls sustainable garden, campus-wide waste management, a bicycle generator, and many others. They have grown on campus and helped to improve the community. “iCREATE’s Innovation Lab was the space of choice to build and work on projects because of it’s open, welcoming environment. There are not many places like that, especially on campus, that will support us. They supported growth, failure, and allowed us to keep trying and working.”

“The worst part of being on this roller coaster is that you don’t know when the bumps are coming, but this is what made me realize – the roller coaster is kinda fun,” Julian said.

CentriSeed Innovation has grown from his original group of 3-4 people in his sophomore and junior year to an average of 30 people who come to each general body meeting now. “It’s a full time job. Starting a club isn’t as fancy or pretty as it sounds.” The name change is to support the growth of the club so that it can continue to expand. “It’s a three part name. It’s the center of innovation, and beginning of new ideas to sprout.” Julian wants Centriseed Innovation to reach and flourish on other college campuses as well.

As Julian graduates this May 2017 with his Electrical Engineering degree, he is excited and confident about his plans moving forward with the skills he has acquired in Electrical Engineering and leadership.

![[ File # csp7403202, License # 3176625 ] Licensed through http://www.canstockphoto.com in accordance with the End User License Agreement (http://www.canstockphoto.com/legal.php) (c) Can Stock Photo Inc. / alexmillos](https://you.stonybrook.edu/researchtech/files/2016/03/UserManual-832x1024-v2cjqf-832x1024.jpg)